Our history

In 1859 Francesco Glisenti, a patriot of Mazzinian sentiments, founded Glisenti foundry together with his brother Isidoro and soon they specialized in the production of weapons and bullets for the Army.

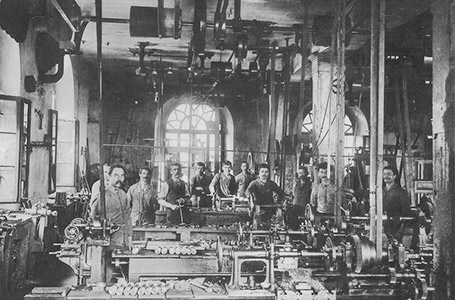

The Foundry rose up as a production unit integrated into an industrial system, formed of Alfredo Mine, Tavernole blast furnace, two hammer forging workshops and a machining workshop.

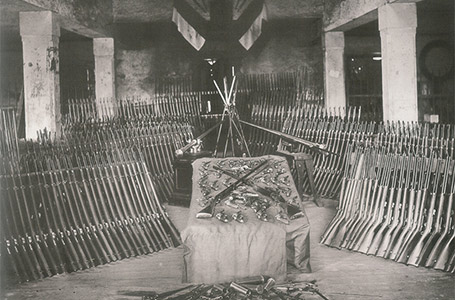

Glisenti foundry became an impressive war machine, at the service of both Italian and foreign governments. Highly specialized in war weapons production, in the following years it supplied the Italian Army with about 60,000 central percussion pistols caliber 10.35 (the famous “Glisenti caliber” model 1872), 25,000 Vetterli rifles and the French government with 24,000 Chassepots rifles.

On 23rd August 1890 King of Italy Umberto I, Queen Margherita and the Prince of Naples Vittorio Emanuele, the future king, visited Carcina facility guided by the Member of Parliament Giuseppe Zanardelli and this fact sealed the prestige of this industrial installation.

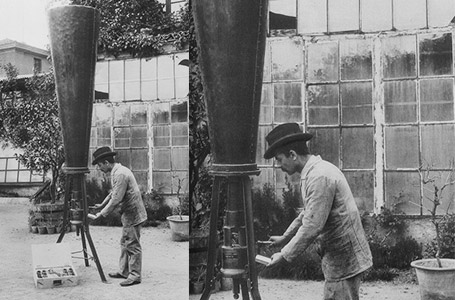

In 1898 Eng. Alfredo Glisenti tried to diversify production following in the forefront the modern automobile adventure; he purchased patent of gas engines from Prof. Bernardi of Padua and he patented himself a three wheels car with three speed gear that unfortunately didn’t obtain any achievement.

In 1907 all the mining and weapon-making activity was devolved and at the same time Guido restructured the cast iron foundry.

In the 50’s the whole production was standardized focusing on cast iron items for Fiat trucks basements and hydraulic pumps. In those years, the first experiments of ductile iron casting took place and the tests with that particular iron already developed in the US made Glisenti one of the first foundries in Europe that started producing ductile iron on industrial basis.

In 1980 the foundry was acquired by Dalla Bona family that marked a revival for the Company despite the critical period for Italian manufacturing industry: the new owners chose to specialize in the production for tractor industry, earthmoving machines and industrial vehicles. In 1987 a new and modern horizontal molding plant was installed and the furnace division was powered in order to reach a total capacity of 150 tons of molten metal.

That choice proved successful and at the beginning of 2000 a new vertical molding plant allowed Glisenti to complete product range, producing medium and high series items of small dimensions for automotive sector.

In 2007 a new strengthening plan for furnaces was completed and thanks to its five furnaces Glisenti reached a daily capacity of 250 tons of molten metal.

In 2010 during the celebration for Confindustria centenary, Glisenti received a special prize for its 150 years of activity in a ceremony at Confindustria headquarter in Rome.

At the end of 2010, another great investment led Glisenti to expand its machinery and to rebuild cores division: a new automatic system for cold box cores preparation and handling was installed. This new plant highly improved the working environment, using smelly products no more.

In 2014 the Horizontal molding plant of 1987, already restored in 2007, was completely replaced by a new molding flask plant that granted better productivity, better quality on products using the best available technologies.

In 2016 shot blasting machine located next to vertical molding plant was replaced and following “Industry 4.0” policy a three-year program of investments was approved, in order to continuously upgrade production technologies, empower production capacity and reduce environmental impact.

In 2017, a three-year program of plant investments is implemented, in the logic of Industry 4.0, which re-upgrades production technologies, further enhancing production capacity and reducing environmental impacts. In 2018, we complete the acquisition of the "Lead Time" foundry in Caldarola (MC), in which we have been involved since 2003, and with which we determine an effective integration in products to supply markets.

Today, we are aware of the many and complex challenges to which progress will confront us: new and continuous process and product improvements will be essential to be able to not only satisfy, but indeed anticipate the changing needs of customers. For these new challenges, we must equip ourselves by integrating a focus on organization and economic logic with innovation, courage and creativity; which is basically what we have had to and been able to do in over 160 years of history.